Electric Robotic Gripper - Yamaha

Electric gripper

Electric gripper YRG-series enables gripping force control, speed control, acceleration control, multi-point position control, and workpiece measuring.

YRG Series

Electric grippers for the RCX340 controller

Easy to operate since YAMAHA robot language gives unified control

An electric gripper achieving the highly accurate gripping force, position, and speed control that are difficult to achieve by conventional air units. The gripper is controlled only with one 4-axis controller RCX340. As the data exchange with the host unit, such as PLC is not needed, the setup or startup can be performed easily.

Feature

01Electric gripper for high-precision gripping power, positioning, and speed control

YRG delivers gripping power control, speed and acceleration control, multi-point positioning, and measuring of workpieces, which have been difficult for air-driven devices. The YRG proves a flexible fit for a wide range of applications.

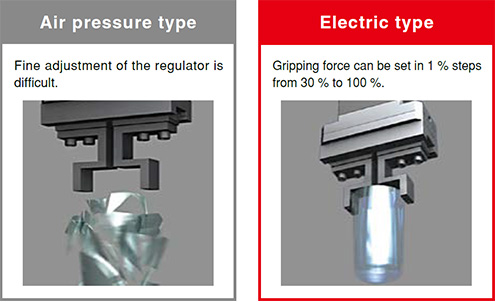

Gripping force control

The gripping force can be set in 1 % steps. Workpieces that are easy to break or deform, such as glass or spring can be gripped. The gripping force is constant even when the finger position changes.

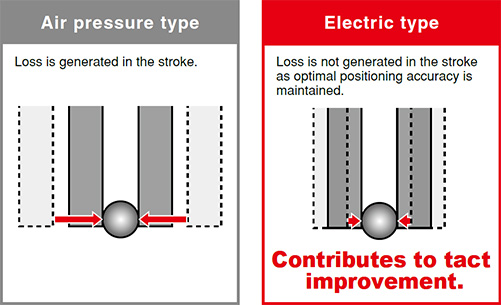

Multi-point position control

The finger can be set to a desired position according to the workpiece size. This contributes to efficiency improvement of lines with different workpiece sizes and materials mixed and lines with many setup steps.

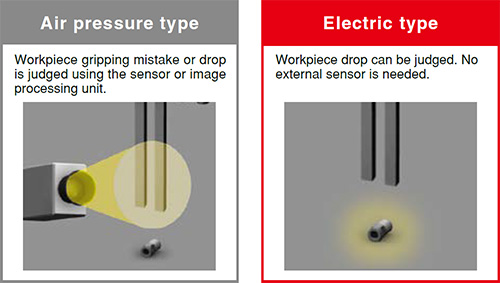

Workpiece presence check function

The electric gripper outputs the HOLD signal. Workpiece gripping mistake or workpiece drop during transfer can be checked. No external sensors are needed.

Measuring function

The gripped workpiece can be measured using the position detection. Use of this function makes it possible to correctly judge what portion of the workpiece is gripped.

Zone range function

Use of this zone range function makes it possible to judge the size OK/NG and check for slant insertion.

Speed control

The speed and acceleration can be set in a range of 20 to 100 mm/sec. in 1 % steps (singe cam and three fingers type). The gripper can gently touch workpieces that are vulnerable to impact, such as lenses or electronic components.

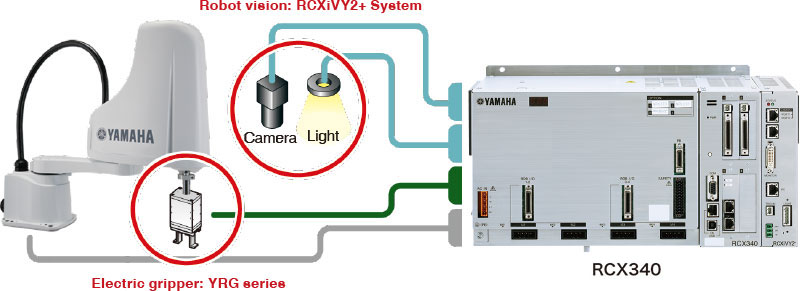

02Controllable with a single controller

One multi-axis controller RCX340 unit can control all robot operations including a gripper (using a control board installed in the RCX340). Needs no data exchange with the host device such as PLC, so set-up and start-up are amazingly simple.

03Combination with a vision system supports wide ranging applications

Even sophisticated systems can be easily configured by using the YRG series gripper in combination with a controllerintegrated robot vision "iVY system".

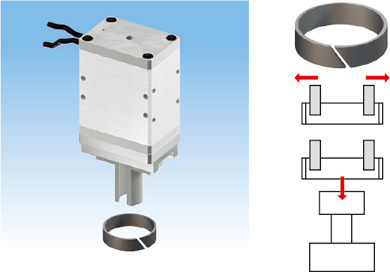

04Protective (non-warp) conveying of plastic rings, etc.

Measuring function (maintains workpiece contours)

Gripping power control (maintains workpiece contours and prevents scratches on workpiece)

Speed control (maintains workpiece contours & prevents scratches on workpiece)

Multi-point position control (for multiple types of workpieces)

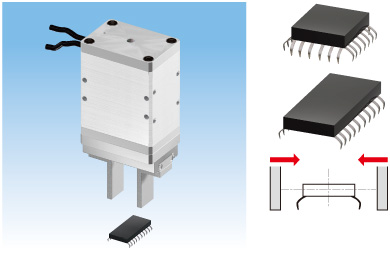

05Chip assembly conveying Anti-warp and lead protrusion checks

Measuring function (checks lead protrusion dimensions)

Gripping power control (maintains workpiece contours and prevents scratches on workpiece)

Speed control (maintains workpiece contours and prevents scratches on workpiece)

Multi-point position control (for multiple types of workpieces)

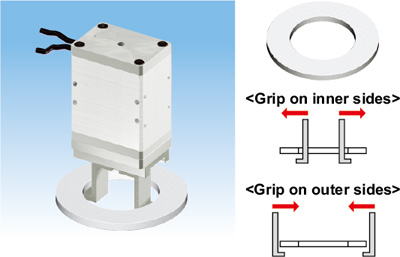

06Conveying and dimension checks of large, flexible, lightweight items

Measuring function (measures workpiece dimensions)

Gripping power control (prevents warping of workpiece)

Speed control (prevents scratches on workpiece)

Multi-point position control Cuts down on setup/changeover tasks (improves productivity)

07Gripping force comparison of electric grippers